Why are our jewelry laser welders so popular?

In the jewelry industry, efficiency and quality are key to success. Our laser welders are the industry’s top choice thanks to their core advantages.

• Precise and flawless: The welds are smooth, strong, and virtually invisible. Whether repairing a broken chain or reinforcing a gemstone, we achieve flawless results, enhancing the value of your work.

• Easy to use: The user-friendly design allows even beginners to quickly master the machine. Eliminate complex operations and focus on design and innovation.

• Multi-purpose: Suitable not only for jewelry but also for welding small, delicate items like glasses and watches. This versatile machine helps you expand your business and increase profits.

• Environmentally friendly and safe: No chemical solder is used, resulting in a pollution-free and odor-free work environment, creating a cleaner and safer working environment.

Choosing our laser welders means choosing efficiency, quality, and high profits.

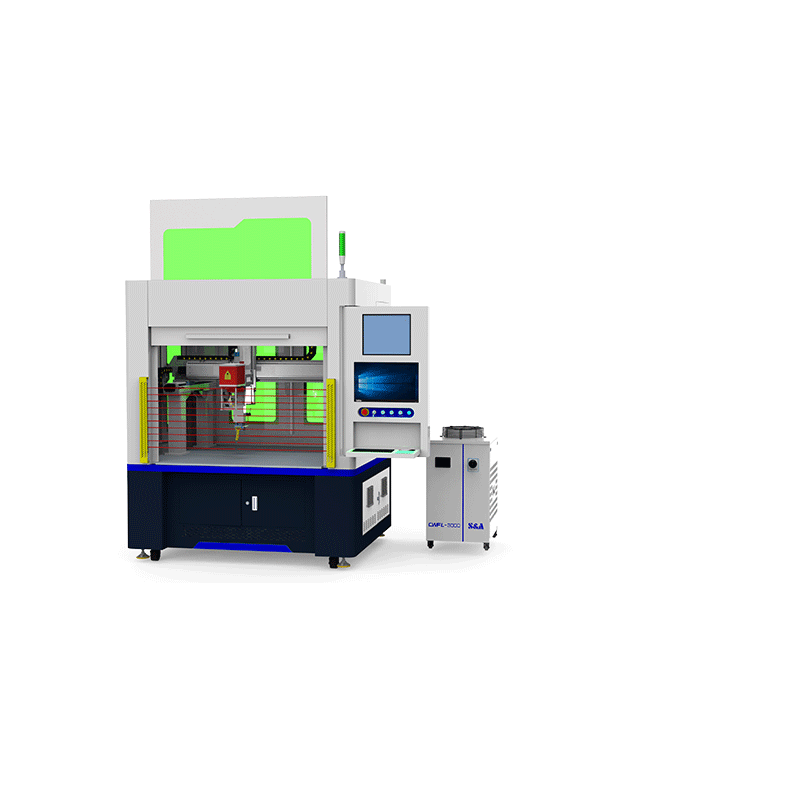

Why are our battery laser welding machines so popular?

In battery manufacturing, efficiency, precision, and safety are key. Our laser welding machines are the industry’s top choice thanks to their core advantages.

• High Speed and Efficiency: Utilizing galvanometer technology, welding speeds are ultra-fast, significantly reducing production cycle times. This makes handling large-volume orders easy and efficient.

• Precision and No Blind Spots: A four-axis linkage system flexibly handles complex structures, enabling seamless welding of both prismatic and cylindrical batteries.

• Safety and Reliability: The fully enclosed design isolates the laser from dust and smoke, protecting operators and creating a worry-free production environment.

Choosing our laser welding machines means choosing high efficiency, quality, and safety.

This video shows the details of our YAG Ordinary mold laser welding machine

Our laser welding machines are primarily used in three areas: jewelry, mold repair, and batteries. They efficiently and precisely weld gold and silver jewelry, repair minor damage to various molds, and seal battery tabs and housings.

Laser welding has the advantages of high precision, high efficiency, firm and beautiful welds, small heat-affected zone, and no need for consumables. It can handle delicate work that is difficult to complete with traditional welding, reduce material deformation, and ensure welding quality.

Easy to learn and operate. Our equipment features a user-friendly interface that allows ordinary workers to use it after a short training period. We also provide corresponding operation guidance and technical support for different application scenarios.

Routine maintenance is straightforward. The main tasks are regular cleaning of the workbench, checking the cooling water circulation system, and protecting the lenses. A detailed maintenance manual is provided upon delivery, along with guidance from professional technicians.

Yes, we offer comprehensive pre-sales, sales, and after-sales services. This includes free equipment operation training, technical support, and equipment warranty services. Our technical team is always on hand to ensure the stable operation of your equipment.

The price is mainly affected by factors such as laser power, equipment model, function configuration and degree of automation. We will provide the most suitable equipment configuration solution based on your specific needs and budget.

We’ll reply you within 24 hours.We respect your privacy.