1000W-6000W Laser power

♦Free Sample Testing

♦Free Customization

♦1-on-1 Training

♦Lifetime After-Sales Service

WHAT WE DO

anjeteklaser not only provides high-quality products and solutions, but also offers comprehensive after-sales and tracking services. You’ll receive expert support at every stage of machine installation. We’ll help you understand the installation and operation process and optimize it to maximize your machine’s performance. We are customer-centric, prioritizing quality and service. Regardless of the scale of your project, we’ll provide comprehensive support and solutions to ensure your highest level of satisfaction.

HOT PRODUCT

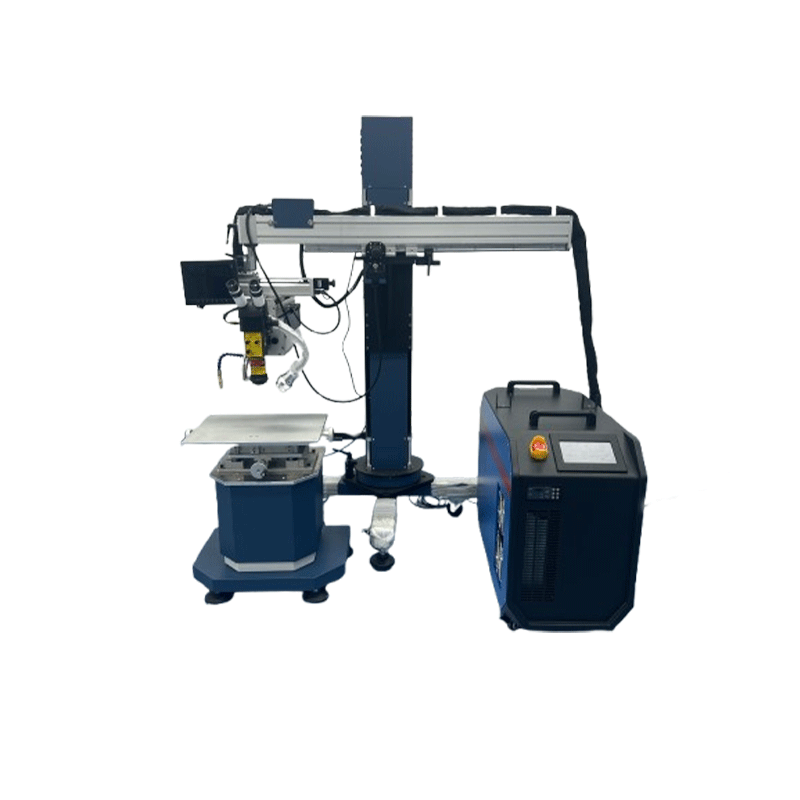

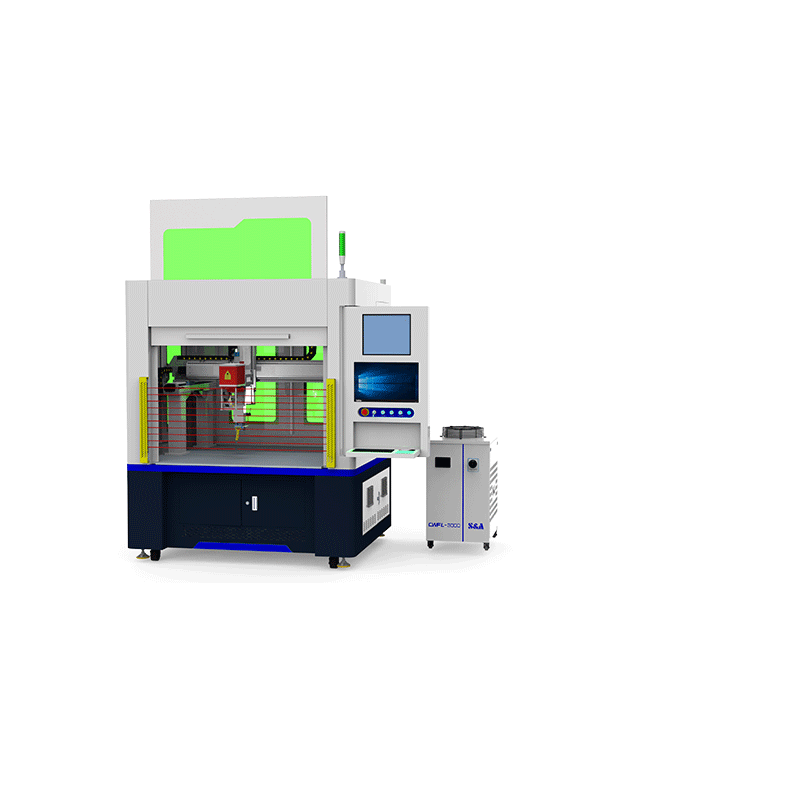

Arm fiber mold laser welding machine

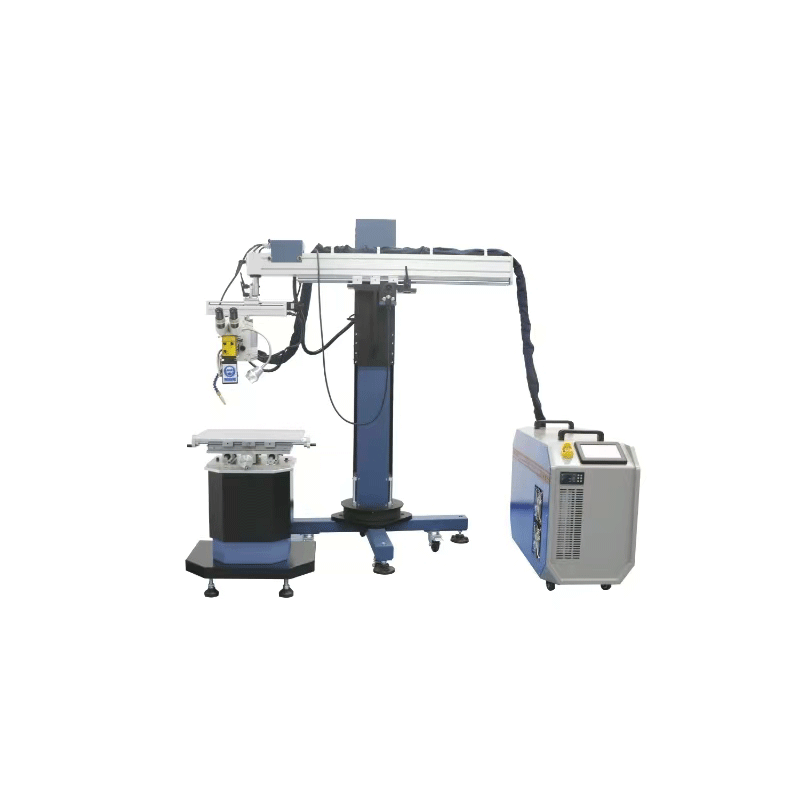

Arm QCW mold laser welding machine

Desktop Jewelry laser welding machine

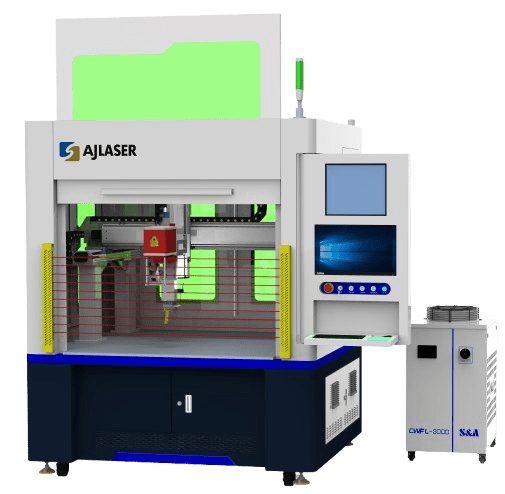

Four-axis enclosed galvanometer laser welding machine

Four-axis open galvanometer laser welding machine

Integrated jewelry laser welding machine

About Us

Precision Welding, Smart Manufacturing.

Founded in 2021, Anje Laser is a dynamic and innovative laser welding technology company. Since its inception, our mission has been clear: to focus on the core field of laser welding and, through continuous technological exploration and process optimization, provide stable, efficient, and precise welding solutions to our global manufacturing customers.

WHY CHOOSE US

As the best laser welding machine manufacturer and supplier in China, Anjetek Laser has many advantages, which will help you get the best products at reasonable prices.

High End Quality

As the best laser welding machine manufacturer in China, our quality control team will ensure that every product you receive is of the best quality. We have professional quality testing equipment to detect the durability of our products.

Best price

We are the source factory and the best laser welding machine manufacturer in China, that's why we can provide high quality laser welding machine with the best price.

Stable delivery time

We understand that stable equipment delivery is key to the smooth progress of your production plans. Therefore, we not only provide high-performance laser welding equipment, but also strive to be your most trustworthy and reliable partner in terms of timeliness.

Free Customization

Free customized solutions, created just for your production. Whether it's your product size, material properties, or production process, we can provide the most suitable laser welding solution.

One-on-one training

We understand that stable equipment delivery is key to the smooth progress of your production plans. Therefore, we not only provide high-performance laser welding equipment, but also strive to be your most trustworthy and reliable partner in terms of timeliness.

7-24 Service

As the best laser welding machine manufacturer, we offer 24/7 immediate response: We collect your feedback to improve our products. We will handle any issues until you are satisfied.

The Benefits Of Laser Welding Technology

Meet High-Speed Production Requirements

With more than 6kW of laser power, the welding speed can be scaled to meet short cycle time requirements.Lasers also require minimal maintenance, so they are ideal for production line automation.

Minimize the Heat Affected Zone

Laser welding can be optimized for minimal heat input. As a result, batteries do not suffer from excessive heating and maintain better mechanical properties..

Join Dissimilar Metals

Lasers can weld dissimilar materials with varying fusion temperatures without the need for filler material. Examples include steel-copper, steel-aluminum, aluminum-copper, and steel-nickel.

Adapt Quickly to Production Variations

Laser parameters can be updated automatically for different needs. This is ideal if you are working with multiple module and pack designs involving various cell types and busbar thicknesses.The welding process can also be updated on the fly for different thicknesses.

Customize Welding Patterns

Because laser welding is a non-contact technology performed remotely, welding patterns can be customized and optimized for each application. This guarantees strong and reliable bonds regardless of the welding area’s size, shape, or location.

Improve Electrical Conductivity

Metals joined by laser welding have an excellent electrical conductivity and better heat management at the welded joints (due to minimal resistance).